THE FIRST SUPPLY:

BB Type 69 Station, Cadmach Press,MOC S7 Steel with IB 35 coating at low temperature.

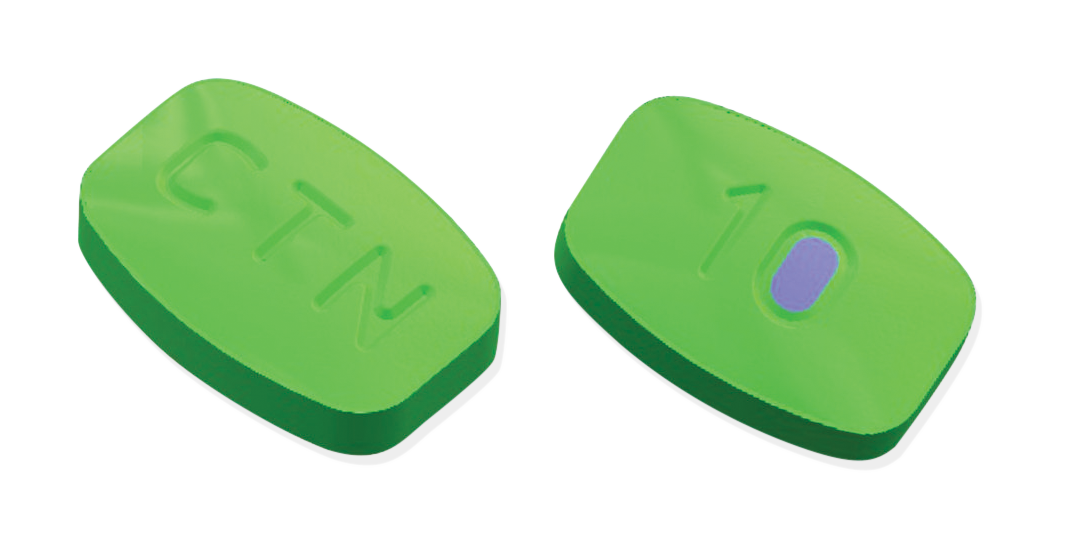

SHAPE & SIZE:

8.00 x 5.50 mm/ PILLOW

ISSUE REPORTED:

Pitting, Rusting, Sticking and Chip-off.

ROOT CAUSE:

Cetirizine 10 mg, is a hydrochloride drug, which leads to pitting and rusting, which gradually forms porosity on cavity, further leading to sticking.

This was an uncommon challenge, which called for R&D. To eliminate the above issues, we tried multiple options,

and resultantly we helped our client to overcome the above issue.

BB Type 69 Station, Cadmach Press,MOC S7 Steel with IB 35 coating at low temperature.

Change MOC to Sliepner Grade Steel with ENI coating on Tip and Body, and Cavity with Matt finish.

ChangedMOC to D2.

We changed tooling type “D Type” Cadmach C300, 49 Stn., Tableting Machine.We modified the Tooling design –(Cavity Design.) with MOC K340, Hard Chrome Plating on Tip & Body and Cavity with Matt finish.

Changed MOC to 440C in “BB Type” Tooling. Tip and Body with Hard Chrome Plating and Cavity with Matt finish.

We made with MOC K340 with wet blasting CrCn Coating at high Temp. and Cryogenic Treatment, this remedy worked out and almost our issue got resolved.

From 1st supply till 5th supply, we were on and off, we tried different MOC with different coatings, polishing the cavity and so on, with unsatisfactory results. But, our sixth supply was a bang on – the issues were permanently eliminated with successful results.

To access this article, please fill out the form below.