With the advancement in technology and wide acceptance of tablets, tabletting machine a must-have accessory in the pharmaceutical industry. A Today, pharmaceutical tablet press machine plays an integral role.

A Tablet Press Machine is an electro-mechanical device. It is used to compound pharmaceutical powder into tablets. It uses force to compress powder into tablets of uniform sizes, shapes, and thickness. It may also be used to manufacture tablets of other industries such as cosmetics, cleaning products, and catalysts for the petrochemicals. A Tablet Press Machine is also known as Tablet Compressing Machine or Tableting Machine.

Tablet making process involves using die and punches to compress powder particles to form pills/tablets.

Hence, tablet press tooling has become an integral process in the machine design.

In the recent past, pharmaceutical tablet machines have been technologically updated and upgraded to ensure precise user control and convenience while guaranteeing higher productivity.

This helps to provide versatility, high-speed, automated and easy maintenance.

TABLET PRESS MACHINE PROCESS

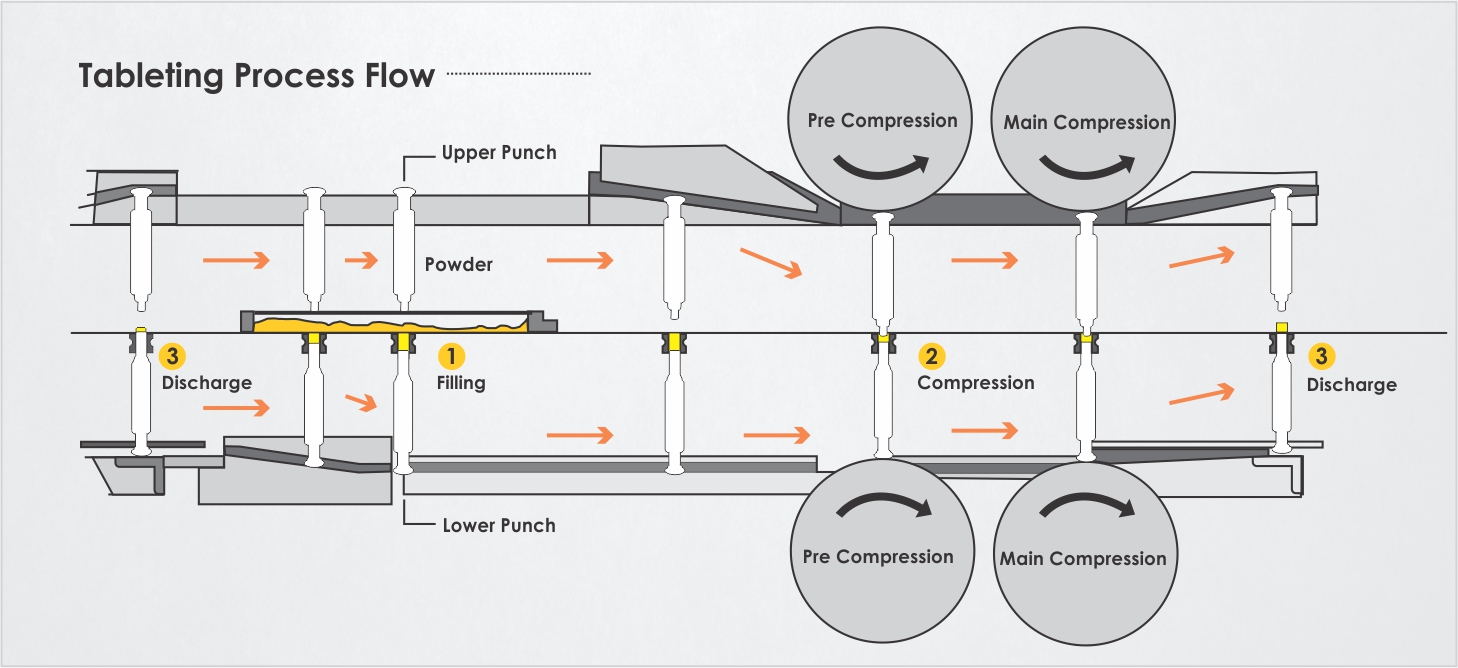

The process of making a tablet starts with the formulation of a powder. The powder is generally a mixture of several components. Before the powder is fed to a tablet press it undergoes a process of granulation to achieve the desired particle size distribution. After granulation, the powder is fed into a hopper on the tablet press from where it is metered into a cavity formed by a die and the upper and lower punches.

The dies and punches define the uniformity of size, weight, and shape of the finished tablet. The dies and punches are usually known as tablet tools.

BASIC COMPONENTS OF TABLET PRESS

- Hopper – to hold the materials that are to be compounded

- Die – it is the cavity that moulds the size and shape of the powder

- Punches – it compresses the materials within the die

- Cam track – ensures smooth movement of the punches

- Feeding mechanism –moves the materials from the hopper to the die

TYPES OF TABLET PRESS MACHINES

Tablet PressMachines are available in Single Station or Multiple Stations.

SINGLE PUNCH TABLET PRESS MACHINE

Single Punch Tablet Press Machine is also called eccentric or single station press machine. It is one of the simplest forms of tablet press machines. However, with comparatively low production capacity.

Depending on the design, you can opt for manually operated or fully automated control.

The single station pharmaceutical tablet compression machines are:

- Structurally small, hence, suitable where space is limited

- High utilization ratio

- Convenient to operate and user-friendly

- Low noise level

- Cost effective in clinical trials and R&D

These tablet press machines use a single set of the station to process powder to the desired compaction and size. It consists of a pair of upper and lower punch system and a die.

MULTIPLE STATION TABLET PRESS MACHINE

As the name suggests, Multiple Station Tablet Press Machine or Rotary Press Machine has multiple or multi-station presses.

Unlike the single press, this tablet press machine has a complex design and structure. The set of dies with both lower and upper punches are in a constant rotary motion.

This allows for machine head to rotate as the punches move up and down, while the fixed cam tracks and controls the compression process.

Multiple Station Tablet Press Machines are –

- Suitable for large scale production

- Fully automated systems with touch screen HMI

- Cost effective in large scale production

- Independent control of hardness and weight